Revolutionizing Material Handling: The Advantages of Bespoke Designed Conveyor Rollers

In today’s fast-paced world, businesses need to constantly adapt and improve their operations to keep up with the competition.

Material handling is a critical aspect of any business, and the use of conveyor rollers has been one of the most significant advancements in the field.

However, not all conveyor rollers are created equal, and off-the-shelf solutions may not always be the best fit for your specific needs.

That’s where bespoke-designed conveyor rollers come in. Revolutionizing material handling, bespoke conveyor rollers offer a range of advantages over traditional options.

From increased efficiency and productivity to reduced maintenance costs and improved safety, these customized solutions can help take your material handling to the next level.

Let’s explore the benefits of bespoke designed conveyor rollers and why they should be considered for any business looking to streamline its operations.

The importance of bespoke designed conveyor rollers

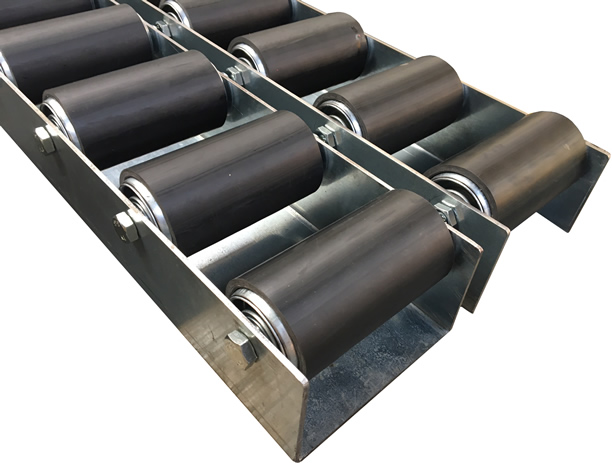

Conveyor rollers are an essential component of any material handling system. They are used to transport goods from one place to another, often over long distances.

While off-the-shelf conveyor rollers are readily available and can be a cost-effective solution in some cases, they may not always meet the specific needs of a business.

This is where bespoke designed conveyor rollers become essential. They are customized to meet the specific requirements of a business, taking into account factors such as the weight and size of the goods being transported, the speed of the conveyor system, the environment in which it will operate, and the space available for installation.

Bespoke conveyor rollers are created using advanced technology and manufacturing techniques, ensuring that they are durable, efficient, and long-lasting.

They are precision-engineered to provide the highest levels of performance, reliability, and safety. By choosing bespoke designed conveyor rollers, businesses can optimize their material handling operations and achieve significant cost savings in the long run.

Advantages of bespoke designed conveyor rollers

There are several advantages to using bespoke designed conveyor rollers. One of the most significant benefits is increased efficiency and productivity.

By using customized conveyor rollers, businesses can optimize their material handling operations, reducing the time it takes to transport goods from one place to another.

This can have a significant impact on the overall productivity of the business, allowing it to handle larger volumes of goods in a shorter amount of time.

Another advantage of bespoke designed conveyor rollers is reduced maintenance costs. These customized solutions are designed to be durable and long-lasting, reducing the need for frequent repairs and replacements.

This can result in significant cost savings over time, as businesses do not have to invest in new conveyor rollers as frequently. Additionally, bespoke designed conveyor rollers are often easier to maintain, as they are designed to be more accessible and user-friendly.

Improved safety is another benefit of bespoke designed conveyor rollers. These customized solutions can be designed to meet the specific safety requirements of a business, reducing the risk of accidents and injuries in the workplace.

By ensuring that the conveyor system is safe and reliable, businesses can provide a better working environment for their employees and reduce the risk of liability.

Cost-effectiveness of bespoke designed conveyor rollers

While bespoke designed conveyor rollers may be more expensive upfront than off-the-shelf solutions, they offer significant cost savings in the long run.

By reducing maintenance costs, increasing efficiency and productivity, and improving safety, these customized solutions can have a positive impact on the bottom line of any business.

Additionally, bespoke designed conveyor rollers can be designed to be more energy-efficient, reducing energy costs and further improving the cost-effectiveness of the system.

Durability and long-term benefits of bespoke designed conveyor rollers

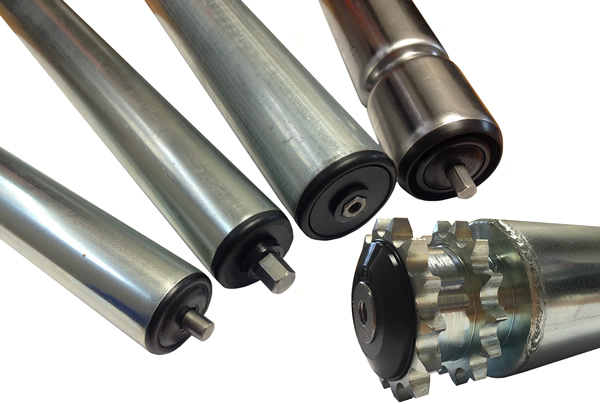

One of the key advantages of bespoke designed conveyor rollers is their durability. These customized solutions are designed to be long-lasting, reducing the need for frequent repairs and replacements.

By investing in high-quality conveyor rollers, businesses can achieve significant cost savings over time, as they do not have to replace the rollers as frequently.

Additionally, bespoke designed conveyor rollers can be designed to be more resistant to wear and tear, reducing the need for maintenance and further improving the long-term benefits of the system.

How to choose the right bespoke designed conveyor rollers for your business

Choosing the right bespoke designed conveyor rollers for your business can be a challenging task. It is important to consider factors such as the weight and size of the goods being transported, the speed of the conveyor system, the environment in which it will operate, and the space available for installation.

Furthermore, it is important to work with a reputable manufacturer that has experience designing and manufacturing customized conveyor rollers.

By working with a trusted partner, businesses can ensure that they are getting a high-quality product that meets their specific needs and requirements.

Case studies of successful implementation of bespoke designed conveyor rollers

There are numerous case studies of the successful implementation of bespoke designed conveyor rollers. For example, a manufacturing company that produces large, heavy products implemented a customized conveyor roller system that was designed to handle the weight and size of their products.

This new system improved efficiency and productivity, reducing the time it took to transport goods from one place to another. Additionally, the new system was more energy-efficient, reducing energy costs and further improving the cost-effectiveness of the system.

Trends and innovations in the material handling industry

The material handling industry is constantly evolving, and there are several trends and innovations that are worth keeping an eye on.

One of the most significant trends is the increased use of automation and robotics in material handling. This includes the use of conveyor systems that are designed to work in conjunction with robots and other automated systems.

Furthermore, there is a growing trend towards the use of data analytics and other advanced technologies to optimize material handling operations.

Conclusion

Bespoke designed conveyor rollers are revolutionizing material handling, offering a range of advantages over traditional off-the-shelf solutions.

From increased efficiency and productivity to reduced maintenance costs and improved safety, these customized solutions can help take your material handling to the next level.

When choosing bespoke designed conveyor rollers, it is important to consider factors such as the weight and size of the goods being transported, the speed of the conveyor system, the environment in which it will operate, and the space available for installation.

By working with a trusted partner and investing in high-quality conveyor rollers, businesses can achieve significant cost savings over time while optimizing their material handling operations.

The material handling industry is constantly evolving, and businesses that stay up-to-date with the latest trends and innovations will be better positioned to succeed in the long run.